Hom sanding siv haum rau pob zeb polishing thiab sib tsoo

Brown fused alumina yog ib qho khoom siv corundum uas tsim los ntawm melting thiab txo peb cov ntaub ntawv raw: bauxite, carbon cov ntaub ntawv thiab hlau filings nyob rau hauv ib tug hluav taws xob arc rauv.Cov tshuaj tseem ceeb yog AL2O3, cov ntsiab lus ntawm 95.00% -97.00%, thiab me me ntawm Fe, Si, Ti, thiab lwm yam.

Silicon carbide yog ib yam khoom tsis muaj zog nrog cov tshuaj formula ntawm SiC.Nws yog tsim los ntawm kub smelting ntawm raw cov ntaub ntawv xws li quartz xuab zeb, roj av coke (los yog thee coke), thiab ntoo chips (ntsev yog xav tau los tsim ntsuab silicon carbide) los ntawm lub qhov cub tsis kam.Muaj ob hom kev sib txawv ntawm silicon carbide, dub silicon carbide thiab ntsuab silicon carbide, ob qho tib si ntawm α-SiC.

Cov yam ntxwv ntawm cov pob zeb sib txawv

1. Marble yog tsim los ntawm limestone.Nws nto muaj cov khoom zoo nkauj zoo nkauj tom qab ua hauv av thiab polished.Txawm li cas los xij, nws cov khoom yog mos heev thiab yooj yim cuam tshuam los ntawm kev cuam tshuam sab nraud.

2. Cov txheej txheej ntawm granite yog ib qho nyuaj thiab belongs rau volcanic pob zeb, thiab nws muaj zoo heev hnav tsis kam thiab corrosion kuj.Nws feem ntau yog siv rau hauv chav ua noj countertops lossis hauv av.

3. Inorganic artificial pob zeb tsis muaj carbon atoms nyob rau hauv, yog li nws hardness yog zoo dua li cov organic dag pob zeb.

4. Qhov ntom ntawm cov pob zeb pob zeb zoo nkauj yog siab, nws yuav tsis nqus dej yooj yim, thiab nws muaj kev sib khi zoo, thiab tus nqi exfoliation zoo dua li cov pob zeb inorganic.Txawm li cas los xij, qhov kev ntxhib los mos zoo ib yam li yas thiab yuav cuam tshuam los ntawm thermal expansion thiab contraction.

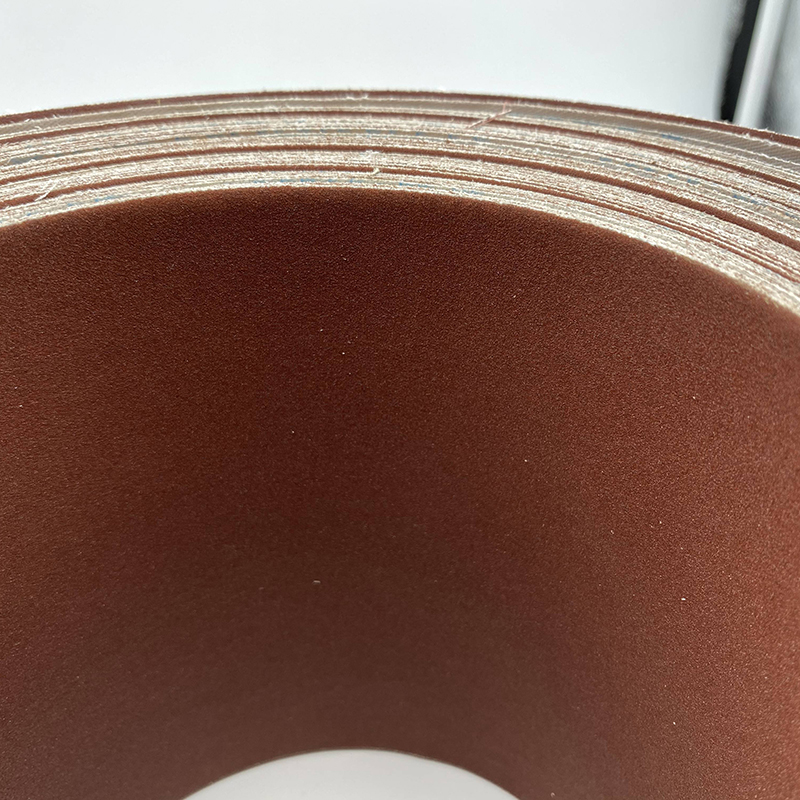

Cov khoom siv hauv paus ntawm txoj siv abrasive yuav tsum muaj qee lub zog thiab me me elongation.

Lub zog ntawm cov khoom siv hauv paus yog ze ze rau lub zog ntawm txoj siv tawv abrasive.Tsuas yog nrog lub zog siab, txoj siv tawv abrasive tuaj yeem tiv taus qhov cuam tshuam ntawm tensile load, alternating load, sib tsoo load thiab expansion load thaum lub sij hawm sib tsoo txheej txheem.

Elongation kuj yog ib qho tseem ceeb heev qhia txog cov khoom siv hauv paus.Yog tias txoj siv abrasive txuas ntxiv zoo heev nyob rau hauv qhov kev txiav txim ntawm sab nraud quab yuam, cov khoom abrasive yuav poob thiab poob lub peev xwm sib tsoo.Extension ntau dhau yuav dhau qhov kev hloov kho tau ntawm txoj siv tawv nruj ntawm lub grinder.Yog li ntawd, txoj siv tawv abrasive tsis tuaj yeem siv.

Txoj kev Polishing

1. Hu rau lub log hom

Txoj siv abrasive grinds los ntawm kev tiv tauj lub workpiece nrog lub log sib tiv tauj.Nws tuaj yeem siv los ua cov txheej txheem ntawm lub voj voog sab nraud, lub qhov hauv lub qhov thiab lub dav hlau ntawm lub workpiece, thiab lub log sib tiv tauj tuaj yeem ua rau hauv ib qho duab los tsim qhov nkhaus ntawm lub workpiece.Kev sib tsoo nrog cov log sib txuas kuj tuaj yeem siv los ua ke nrog kev ua haujlwm tsis tu ncua.

2. Sib tsoo phaj hom

Thaum sib tsoo, txoj siv abrasive hu rau lub workpiece los ntawm kev sib tsoo phaj.Lub siab-sib tsoo phaj muaj cov nyhuv nias thiab feem ntau yog siv rau kev ua haujlwm dav hlau, uas tuaj yeem ua rau thaj chaw sib cuag, txhim kho kev sib tsoo thiab qhov tseeb ntawm qhov chaw ua haujlwm, tshwj xeeb tshaj yog cov flatness.

3. Kev ywj pheej

Lub workpiece yog nyob rau hauv kev sib cuag ncaj qha nrog lub saj zawg zog abrasive siv yam tsis muaj ib yam khoom txhawb lub abrasive siv.Nws siv nws tus kheej yooj yim tom qab siv tensioned los zom los yog polish lub workpiece.Txoj kev no yog ib qho yooj yim los hloov mus rau lub contour ntawm lub workpiece nyob rau hauv ib tug tej yam ntau yam, tshwj xeeb tshaj yog tsis xws li cov duab ntawm lub workpiece, thiab feem ntau yog siv nyob rau hauv cov txheej txheem ntawm txheej molding nto thiab chamfering, deburring, polishing thiab lwm yam txheej txheem.